The Future of Precision Engineering: Investing in CNC Machines

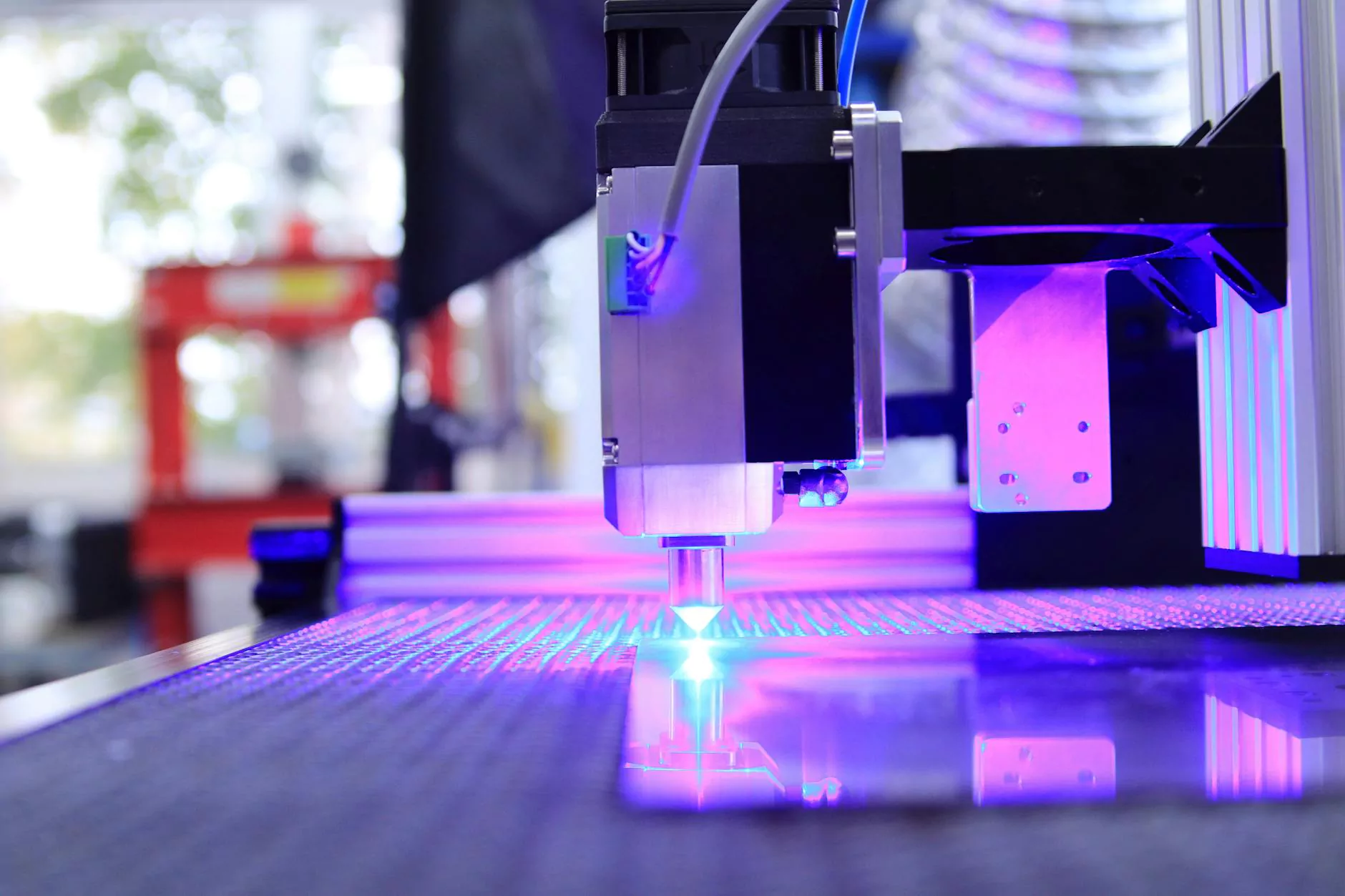

In today's rapidly evolving technological landscape, precision engineering plays a crucial role in the development and manufacturing of high-quality products. A significant factor contributing to this precision are CNC machines, which have revolutionized industries ranging from automotive to aerospace. If you are looking to invest in CNC technology, roc-tech.com is your ideal partner.

Understanding CNC Machines

CNC stands for Computer Numerical Control, which refers to the automated control of machining tools such as drills, lathes, and mills by a computer. These machines are essential for creating components with exceptional accuracy and efficiency. The popularity of CNC machines is primarily due to their ability to produce complex designs with minimal manual intervention.

The Components of CNC Machines

A typical CNC machine consists of various critical components, including:

- Control Unit: The brain of the CNC machine, which interprets the G-code and directs the machine's movements.

- Driving Mechanisms: Comprising motors and actuators that enable movement along various axes.

- Machine Tool: The actual tool used for cutting or shaping materials.

- Feedback System: Sensors that provide the control unit with information about the machine's position and performance.

The Benefits of CNC Machines

Investing in CNC machines through roc-tech.com comes with a variety of benefits that can significantly enhance your manufacturing processes:

- Enhanced Accuracy: CNC machines offer exceptional precision to tolerances of up to +/- 0.001 inches.

- Increased Output: With automation, CNC machines can operate continuously, increasing productivity considerably.

- Flexibility: Easily reprogrammed for different tasks, allowing manufacturers to switch between jobs with minimal downtime.

- Less Waste: Precise cutting translates to reduced material waste, making your production more cost-effective.

CNC Machines at roc-tech.com

At roc-tech.com, we offer a diverse range of CNC machines tailored to meet the varied needs of different industries. Our machines are designed with cutting-edge technology that ensures they meet the highest standards of performance and reliability.

Types of CNC Machines Available

We provide a selection of CNC machines, including:

- CNC Mills: Used for cutting and shaping materials, CNC mills are versatile tools in machining processes.

- CNC Lathes: Ideal for producing cylindrical components, CNC lathes are essential in industries needing intricate and precise designs.

- CNC Routers: Best for woodworking and plastics, CNC routers are perfect for creating detailed designs and shapes.

- CNC Plasma Cutters: These machines are invaluable for metalworking, enabling clean, precise cuts in various metals.

How to Choose the Right CNC Machine

Selecting the right CNC machine requires careful consideration of several factors:

- Material Type: Different machines are optimized for specific materials, so know what you will be working with.

- Complexity of Jobs: Assess the complexity of the designs you will produce to ensure the machine can handle them.

- Budget: Set a clear budget and explore the options available on roc-tech.com that match your financial constraints.

- Support and Service: Ensure that the provider offers robust after-sales support, as maintenance is crucial for optimum performance.

Investing in CNC Machines: A Long-Term Strategy

Investing in a CNC machine is more than just a transaction; it is a commitment to enhancing your production capabilities. CNC machines from roc-tech.com offer unparalleled durability and performance, making them a wise long-term investment for your business.

Cost-Effectiveness Over Time

While the initial investment in a CNC machine may seem significant, the long-term cost savings can be substantial. Consider the following:

- Reduced Labor Costs: Automation reduces the need for extensive labor, allowing you to reallocate resources more efficiently.

- Minimized Material Wastage: High precision means less material waste, lowering overall production costs.

- Lower Maintenance Costs: High-quality CNC machines require less maintenance, reducing ongoing costs associated with upkeep.

Maintaining Your CNC Machines for Longevity

To ensure your CNC machine operates at peak efficiency, proper maintenance is essential. Here are some maintenance tips:

- Regular Cleaning: Keep the machine free from debris and dust to prevent damage and ensure smooth operation.

- Lubrication: Regular lubrication of moving parts can significantly extend the life of the machine.

- Calibration: Regularly check and recalibrate your machine to maintain its precision and accuracy.

- Scheduled Maintenance: Follow a maintenance schedule as recommended by the manufacturer to remedy potential issues before they escalate.

Conclusion: The Future is CNC with roc-tech.com

In conclusion, as industries continue to evolve towards greater efficiency and precision, investing in CNC machines becomes imperative for businesses looking to stay competitive. By choosing roc-tech.com for your CNC machinery needs, you are not just purchasing a tool; you are investing in the future of your production capabilities, ensuring enhanced accuracy, productivity, and cost-effectiveness for years to come.

Explore our extensive inventory of CNC machines for sale and take the first step towards revolutionizing your manufacturing processes at roc-tech.com.