Central Lubrication System Fittings: Ensuring Smooth Operations

In the ever-evolving landscape of the shopping and fashion industry, maintaining efficient operations is crucial for businesses to prosper. One integral component that plays a vital role in ensuring smooth operations in women's clothing businesses is the central lubrication system fittings. By implementing a well-designed and properly maintained central lubrication system, businesses can enhance productivity, minimize downtime, and ultimately thrive in a competitive market.

The Significance of Central Lubrication System Fittings

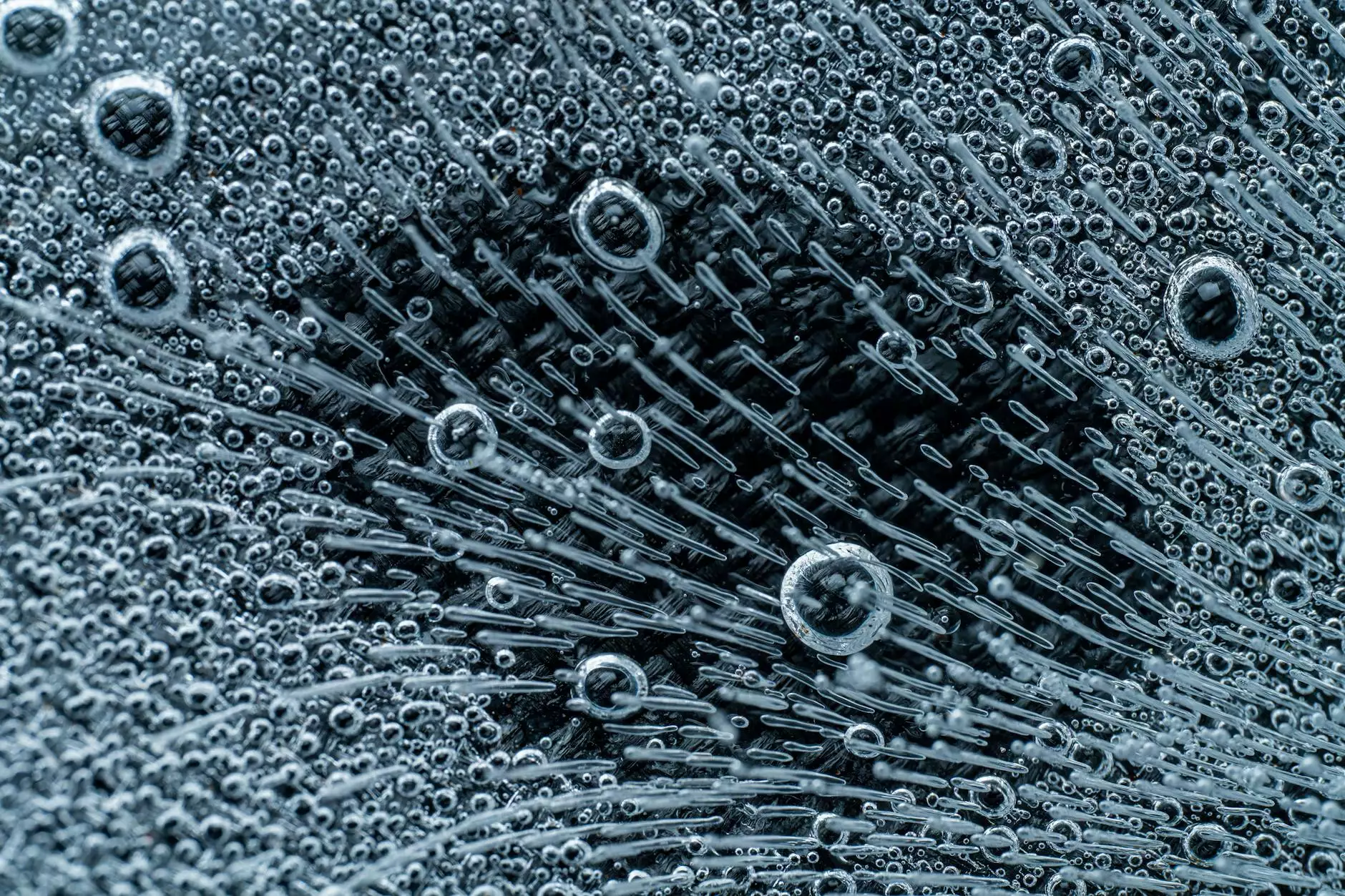

Central lubrication system fittings act as the backbone of a well-oiled machine, quite literally. These fittings connect various lubricating points within a women's clothing business, allowing for a centralized approach to lubrication. The significance lies in the ability to distribute lubricants automatically, precisely, and at appropriate intervals throughout the operating machinery.

By using central lubrication system fittings, businesses can eliminate the need for manual lubrication, which can be time-consuming and prone to human error. Instead, a system of pipes and connectors distributes lubricants to designated points, ensuring optimal performance and longevity of equipment.

Improved Equipment Performance

Efficient equipment performance is essential in the shopping and fashion industry, where time is of the essence and responsiveness to customer demands is key. By utilizing central lubrication system fittings, businesses can improve equipment performance in several ways.

Firstly, central lubrication systems ensure consistent and appropriate lubrication, reducing friction and wear on moving parts. This, in turn, leads to smoother and quieter machinery operation. Ensuring optimal equipment performance not only enhances the quality of products but also provides a pleasant shopping experience for customers.

Secondly, central lubrication systems contribute to the overall reliability and durability of equipment. By regularly maintaining lubrication levels, businesses can prevent premature wear and avoid unexpected breakdowns. This helps minimize downtime, allowing for uninterrupted operations and ensuring timely delivery and availability of women's clothing products.

Enhanced Productivity and Cost Savings

Central lubrication system fittings bring forth a range of benefits that directly impact a business's productivity and bottom line. Effective lubrication reduces the need for frequent manual interventions, freeing up valuable time for employees to focus on more critical tasks and improving overall productivity.

Furthermore, centralized lubrication eliminates the possibility of over-lubrication or under-lubrication, both of which can have detrimental effects on equipment performance and lifespan. By precisely distributing the required amount of lubricant, businesses can avoid unnecessary costs associated with excessive lubrication and equipment repairs.

Additionally, the avoidance of unplanned equipment breakdowns and reduced maintenance requirements can lead to substantial cost savings in the long run. Investing in central lubrication system fittings is not only a wise decision for the present but also a strategic move towards long-term sustainability and profitability.

Maintaining Competitive Advantage

In the competitive landscape of the shopping and fashion industry, maintaining a competitive advantage is crucial for businesses. By investing in central lubrication system fittings, companies can differentiate themselves from competitors by ensuring smoother operations and enhanced equipment performance.

Customers value businesses that consistently deliver high-quality products while minimizing disruptions. The incorporation of central lubrication systems demonstrates a commitment to reliability, efficiency, and superior customer service, which can contribute to building a loyal customer base and attracting new customers.

Conclusion

Central lubrication system fittings form an essential component of women's clothing businesses, enabling smooth operations, improved equipment performance, enhanced productivity, and cost savings. By implementing these fittings, businesses can reduce downtime, prevent equipment breakdowns, and maintain a competitive advantage in the shopping and fashion industry.

Investing in central lubrication system fittings is not just a practical decision, but a strategic move towards operational excellence and long-term success. By prioritizing the centralized distribution of lubricants and ensuring optimal equipment maintenance, businesses can thrive in an industry that demands constant innovation, efficiency, and top-notch customer satisfaction.